Polished concrete and epoxy are two of the most popular flooring systems for residential, commercial and industrial settings.

Both offer multiple compelling benefits you don’t see in other flooring materials. But there are applications where you should definitely choose polished concrete over epoxy – and vice versa.

We’ve prepared a simple guide to help you understand what these two materials are. Find out which flooring system works best for your building project.

Polished concrete flooring

Concrete is the most common substrate used for commercial and industrial flooring. It has three basic components: cement, water and aggregate (rock, sand, or gravel).

Many builders value concrete for its innate toughness and durability. But when polished, concrete becomes even stronger and more resistant to damaging.

Sometimes contractors also use commercial polishing compounds to make the floor more shiny and dirt resistant.

Epoxy flooring

To produce polished concrete, contractors use heavy-duty machines to gradually grind down the surface. They do this until the concrete becomes smooth and shiny. They then apply sealers to help harden and densify the concrete.

Epoxy may not be as well known as polished concrete, but it has seen its popularity grow over the years. It is used primarily to add another layer of protection to floors.

To make the coating, manufacturers combine epoxy resin with a hardener. The chemical reaction produces a stiff plastic material that is durable and highly resistant to damaging. The material also bonds well with substrate.

There are 5 common types of epoxy flooring:

- Self-Leveling Epoxy

- Epoxy Mortar

- Quartz-Filled Epoxy

- Anti-Static Epoxy

- Epoxy Flake

Comparing polished concrete and epoxy floors

Many builders value polished concrete because of its many advantages. When comparing polished concrete to other flooring materials, it’s often considered a better alternative to vinyl, ceramic tile, wood, and natural stone. Meanwhile, epoxy offers its own set of benefits. This makes it an excellent choice if you want additional protection for your floors.

Let’s find out how polished concrete and epoxy stack up against each other.

Durability

When choosing an ideal flooring option, durability should always be the number one thing to consider. Commercial and industrial floors need to be strong and tough enough to withstand the wear and tear of daily use. Fortunately, both polished concrete and epoxy make excellent choices.

Polished concrete benefits from the innate durability of its base material concrete. Once the mixture sets and hardens, it becomes just as strong as natural stone slabs. It can handle high volumes of foot traffic on an everyday basis. It also doesn’t chip or crack as easily as most other flooring materials.

Epoxy flooring is tough, but not in the same manner as polished concrete. It acts more like a protective coating for your existing flooring material. This enhances the surface’s ability to withstand almost all types of impact. However, it can still get damaged by pretty sharp or heavy objects.

Winner: Polished concrete

Cost

Polished concrete and epoxy are two of the most affordable flooring options in the market. You can find concrete readily available in constructions stores. You also won’t have to spend much for the grinding and sealing process needed to polish concrete.

Installing polished concrete flooring typically costs about $50 per square metre on average. The price could go up depending on the type of finish you want to have. It’s a lot cheaper compared to using hardwood flooring or natural stone.

Likewise, adding epoxy on your flooring won’t cost you an arm and a leg. Since it’s basically applying epoxy resin on existing surfaces, it’s much more cheaper than installing new floors. It initially costs about $30-$35 per square metre for two coats. However, the price does increase to about $80-$100 per square metre if you want to diamond grind your concrete floor. This is often done to give surfaces a more decorative finish.

Winner: Epoxy

Installation time

Between the two featured flooring options, epoxy takes less time to install.

Contractors usually take about 2 to 3 days to finish adding the resin to floors. This involves preparing the surface, applying the first (primer) and second epoxy coats and finishing up with a polyurethane top coat. You do need to wait another day before you can walk on the coated surface.

If it’s for a garage, it will take 7 days before you can drive your car over the epoxy flooring. That’s the average cure time for 100% solids epoxy.

Meanwhile, polished concrete takes an average of 3 to 6 days to finish its installation. About 2 to 3 days of it are spent on pouring the concrete mixture and letting it set. The remaining days are then spent on polishing the surface and applying and drying the sealer.

Concrete typically begins to harden as soon as it is poured into the installation site. However, it takes about 28 days or so to complete its curing time.

Winner: Epoxy

Cleaning and Maintenance

It doesn’t take much to properly maintain a polished concrete floor. Cleaning it is as easy as dust mopping the surface daily using a microfiber pad. This helps remove dirt particles that can ruin the shine and clarity of your floor.

You can also use clean water and clean mops to wet mop the surface. If you’re going to use an automatic floor scrubber, it should be equipped with a nonabrasive pad.

You can check out our own easy to follow guide on how to clean and maintain polished concrete floor.

Maintaining an epoxy floor doesn’t have to be complicated either. Just like polished concrete, epoxy doesn’t allow any dirt and grit to damage the floor’s surface. You can use a soft bristle broom or commercial dust mop to remove any free debris from the floor.

You can also have your epoxy floor pressure washed and squeegeed as long as it has adequate cove protection. This is perfect if you’re flooring is located in a commercial or industrial setting.

For both polished concrete and epoxy flooring, experts don’t recommend using acidic and other abrasive cleaning agents. These products might only end up doing more damage to your floor.

Winner: Tie between polished concrete and epoxy

Vulnerability to mould and moisture damage

Polished concrete floors offer better protection against mould and moisture damage than unpolished concrete.

When properly finished and sealed, it can prevent moisture from penetrating its surface. Sealers help keep liquid spills from making their way through the pores on the floor. This reduces the chance for mould or mildew to form.

Epoxy also helps prevent spills from penetrating the floor’s surface. However, it can still suffer from moisture damage some other way. The material doesn’t adhere well in damp environments such as in basements.

Since epoxy doesn’t breath after it cures, it basically traps any moisture below the floor’s surface. This can cause several different problems such as the floor’s paint peeling off and bubbles and blisters forming. It can also lead to mould and mildew formations.

Winner: Polished concrete

Chemical resistance

Epoxy flooring works best in commercial and industrial settings. Most coatings in the market are specially designed to withstand harsh chemical exposures. These include coffee spills, household cleaners, seawater, motor oil, hydraulic fluid and petrol.

Some epoxy products have also been shown to resist other chemicals. Examples of these include ammonia, nitric acid, hydrogen peroxide, formaldehyde and sulfuric acid.

On the other hand, polished concrete doesn’t offer much in terms of chemical resistance. Heavy acids and chemicals can corrode your floor’s surface. You’ll have to use acid-resistant coating to protect your polished concrete floor from damage.

Winner: Epoxy

Slip resistance

Another key factor you need to consider is slip resistance. Is your floor safe enough to use on a daily basis without worrying about slipping or sliding?

Despite its smooth and glossy finish, polished concrete is not slippery. The polishing process still allows the surface to retain some of its porous nature. This gives it much more grip compared to unpolished concrete. It also provides better foot traction than other flooring materials such as marble and linoleum.

Epoxy and other resinous coatings are non-porous. This is what gives surfaces that extremely smooth finish. It works fine when dry, but it becomes slippery when exposed to water, oil or mud. You will need to use non-slip additives to make your epoxy floor less slippery.

Winner: Polished concrete

Reflectivity

Both polished concrete flooring and epoxy flooring can help improve your floor’s reflectivity. This is important if you want to make your space brighter. It also provides ambient lighting, which can reduce your energy consumption.

A properly installed polished concrete enhances light reflectivity by as much as 100%.

Meanwhile, an epoxy coating improves the surface’s reflectivity by 300%. In this case, we have a clear winner between the two.

Winner: Epoxy

Environmentally friendliness

There are many reasons why polished concrete is environment friendly. You don’t have to use too many raw materials to produce concrete. In fact, the only things you need are water-based hardeners and stain-resistant treatments. Polished concrete also doesn’t emit volatile organic compounds (VOCs).

If you have a polished concrete floor, you won’t have to worry about efflorescence. This is the crystalline or powdery salt deposits that often appear on regular concrete or natural stone surfaces. The polishing and sealing process prevents this concrete dust from forming.

Epoxy flooring can also be environment friendly, but it depends on the type of product you use. Most epoxy coatings are made from organic resins and hardeners. The polymerisation involved in making epoxy helps make the material less likely to contaminate the environment.

However, not all epoxy products available are eco-friendly. Some variants may have harmful chemicals that can endanger the environment. As a rule, always ask your contractor if they use green epoxies before installing in your home, office or warehouse.

Winner: Polished concrete

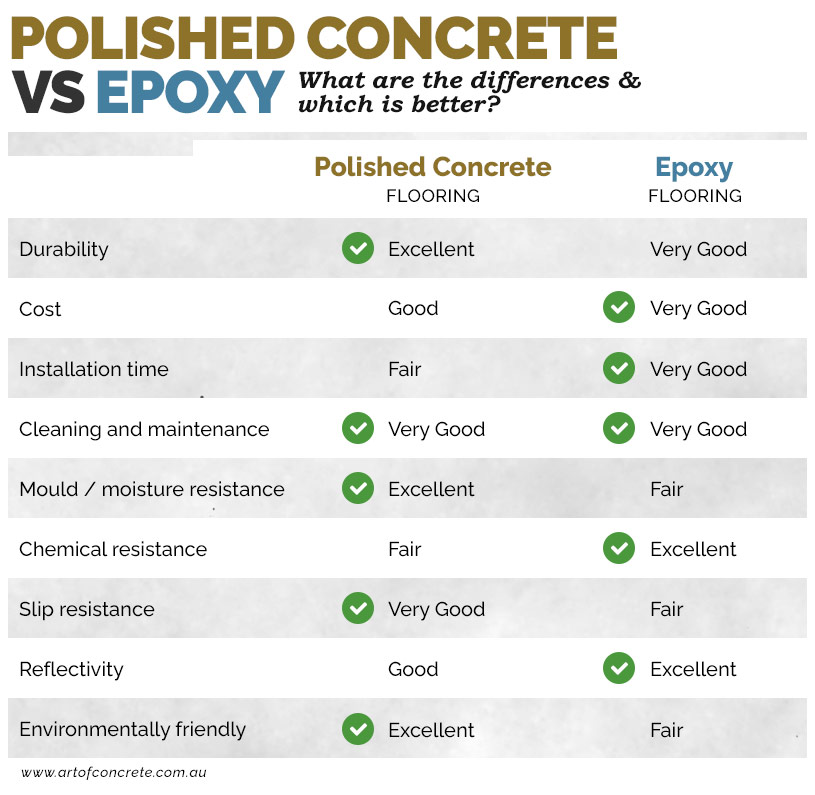

Here’s a rundown of the different categories polished concrete and epoxy are strong and weak in. This should help give you an idea of which of the two flooring options works best for your need.

| Polished concrete | Epoxy | |

|---|---|---|

| Durability | ✔ Excellent | Very Good |

| Cost | Good | ✔ Very Good |

| Installation time | Fair | ✔ Very Good |

| Cleaning and maintenance | ✔ Very Good | ✔ Very Good |

| Mould / moisture resistance | ✔ Excellent | Fair |

| Chemical resistance | Fair | ✔ Excellent |

| Slip resistance | ✔ Very Good | Fair |

| Reflectivity | Good | ✔ Excellent |

| Environmentally friendly | ✔ Excellent | Fair |

Uses

Because of its versatility, polished concrete can be used in a lot of different places. You can often find it commercial establishments such as retail stores, auto showrooms, hotels and restaurants. You can also see it in most modern designed office spaces.

Some industrial establishments have adopted the use of polished concrete floors as well. These include large warehouses and warehouse outlets.

Initially, polished concrete use was limited to shops and warehouses. However, more private residences have started using the material for their flooring. Many homeowners take advantage of polished concrete’s high-glossy look to add style to their abode.

Meanwhile, epoxy is used mainly for commercial settings. Some common examples include offices, clinics, laboratories, showrooms, commercial garages, and commercial kitchens.

Its high resistance to chemicals also makes it ideal for industrial spaces as well. You can see epoxy floors used in mechanical spaces, manufacturing buildings and warehouses.

The table below shows what types of settings where you can use polished concrete and epoxy flooring:

| Polished concrete flooring | Epoxy flooring | |

|---|---|---|

| Residential | ✔ Recommended | Good for Consideration |

| Commercial | ✔ Recommended | ✔ Recommended |

| Industrial | Good for Consideration | ✔ Recommended |

The verdict

Choosing between polished concrete and epoxy floor depends on the type of space you want to install it in.

If you have a store, café or restaurant, you might want to have a polished concrete floor. It’s strong and durable enough to handle high volumes of foot traffic every day. Its high glossy finish already makes polished concrete a stylish addition to any room. But if you want to take it up a notch, you can also combine it with different stains and paints.

If you need protection from spills, especially oils and chemicals, you will want to consider coating your floor with epoxy. It helps protect your floor from impact damage, which is necessary for workplaces such as factories and warehouses. It also makes surfaces more resistant to chemicals such as oil, gasoline and transmission fluid. This can be a godsend if you have a machine shop or a commercial garage.

Contact us for more information and advice. We specialise in both polished concrete and epoxy floor installations. If you need help in choosing which of the two options works best for your space, we’re more than happy to assist. We will design and create the most functional and stylish flooring solution for you.