We specialise in designing and creating polished concrete floors for commercial and high end residential premises of the highest quality in and around Perth.

Read on for an overview of our services or visit the portfolio page for more visuals.

Contact us and we will guide you through your options to create the perfect solution for your project and budget.

External Honed Concrete

External honed concrete is the grinding of an exterior concrete surface using diamond tooling.

Honed concrete achieves a flat, smooth finish making it an ideal choice for:

- pool surroundings

- patios

- driveways

- outdoor entertaining areas

- and many more.

To achieve such a finish, the existing concrete is mechanically ground until the desired level of stone/aggregate (either full exposure or hit and miss) is reached. We then hone the concrete to a suitable grit and apply a sealer to protect the surface.

Non-slip options

We offer several top coat sealing options. For example, we can apply a surface coating containing a non-slip additive. This will sit on the surface of the concrete so the non-slip additive can provide the correct amount of adhesion.

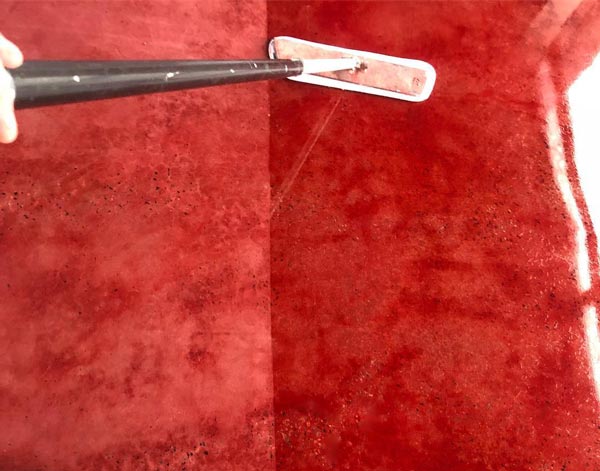

Internal Grind and Seal

Grind and Seal is a cost effective method to polish concrete floors. We grind back the top layer of concrete to show as little or as much stone as you desire.

There are three levels of stone exposure:

- nil exposure

- minimal exposure (1-2 mm)

- full exposure ( 4-5 mm).

After the initial grinding we will use finer diamonds to remove visible scratching and get a flat surface ready for grouting. At this point we can also dye the concrete if you want to change the colour of your floor.

After finely polishing, we will grout your floor to fill all cracks and pin holes (around 80% of the holes can be filled successfully). This results in a super smooth glass like surface.

As the final step, we will seal the concrete with a surface penetrating clear coat sealer to give your floor its shiny appearance and protect it from staining.

Grind and seal concreting is suitable for both residential and commercial purposes.

Indoor applications are ideal, but we can also provide outdoor installations.

Industrial / Commercial Polished Concrete

Do you want to refresh the appeal of your retail space or improve the maintainability and function of your industrial flooring?

Industrial polished concrete flooring is your ideal surface.

Our modern concrete polishing techniques enable you to choose the ideal look and function for your floor’s usage.

Polished concrete floors combine the hardness of concrete and the timeless look of tiles. It is as practical as it is visually stunning.

This the perfect floor surface for your commercial and industrial spaces, including:

- Factory Floors

- Distribution Centres

- Warehouses

- Industrial Sheds

- Commercial retail spaces

- School common areas

- Customer or patient lobbies

- Churches and other community spaces

- Coffee shops and other retail areas with an “industrial” feel

Talk to us as early as possible in your building project, so we can assist you in choosing the best type of polished concrete flooring and schedule the ideal installation time.

Mechanically Polished Concrete

Mechanically polished concrete involves a lot more steps than a ‘grind and seal.’ The method results in a smoother, more durable high gloss concrete floor that’s easy to maintain. It also which offers a wide variety of customisations and finishes (matt, satin and high gloss).

With all the options below we grout the floor in order to fill any of the remaining pin holes/cracks in the concrete.

Polished Concrete Finishing Options:

Full stone exposure – To accomplish full stone exposure, we grind over the concrete floor until all the stones exposed. Once this is reached, we grind the floor to remove scratches then we begin the polishing stage. Read below to learn more.

Salt and pepper (hit and miss) – to achieve the salt and pepper look we grind until we reveal only parts of the stone/aggregate, once we are happy with the amount of stones exposed, we proceed to the polishing stage. Read below to learn more.

Surface polish (minimum/no stones) – in order to get a surface polish it is best when the concrete is poured to suit this type of finish, the concreters need to pour your concrete completely flat. This being because we do not ‘grind’ the concrete but go straight to the polishing stage in order to prevent the exposure of stone.

Benefits of Using Polished Concrete

Polished concrete offers several advantages not usually seen in most other flooring options. For instance, the material provides the same strength and durability as natural stone but at a fraction of the price. It’s also versatile and workable enough to be used in different designs.

The following are some of the benefits of using polished concrete floors:

- Highly durable

- Cost-effective

- Easy to maintain

- Stain-resistant

- Invulnerable to mold and moisture damage

- No efflorescence (concrete dust) build up

- Less slippery

- Versatile

- Highly reflective

- Environmentally friendly

Still having second thoughts about which flooring type to use for your commercial space? See our analysis of the advantages and benefits of polished concrete floors vs. epoxy floors.

Green benefits: passive lighting and temperature control

Did you know that modern polished concrete floors in Perth can improve indoor brightness and heating or cooling?

- By reflecting daylight or any other light deeper into spaces, polished concrete floors can reduce your need for artificial lighting.

- During warm days, a polished concrete floor acts as a “heat sink,” slowly absorbing any heat without immediately radiating it to the rest of the interior. This helps reduce the need for more mechanical cooling.

- In colder months, the same floors can be used to absorb heat from daytime sun and slowly release it overnight, helping warm interiors without extra heating.

To get the most out of polished concrete floors’ passive lighting and temperature control in Perth’s climate:

- Be strategic with where and how you position windows and add shading (i.e., eaves, blinds or curtains). This maximises winter heat gain and minimises summer overheating.

- Add proper insulation beneath the concrete slab. This ensures any thermal mass benefits aren’t lost to the floor foundation or ground below it.

- Avoid covering polished concrete floors with insulating materials (e.g., carpets or rugs), especially in sun-exposed areas.

If you’d like to a more detailed description of our installation process, click here to see how polished concrete floors are installed

Start your project with Perth’s concrete specialists today

From design advice to flawless execution, Art of Concrete delivers polished concrete flooring that performs as beautifully as it looks.

Do you need custom polished concrete overlay floors? We’re the concrete experts you can trust. Contact our Perth team for advice or a quote, and get started.